Defence

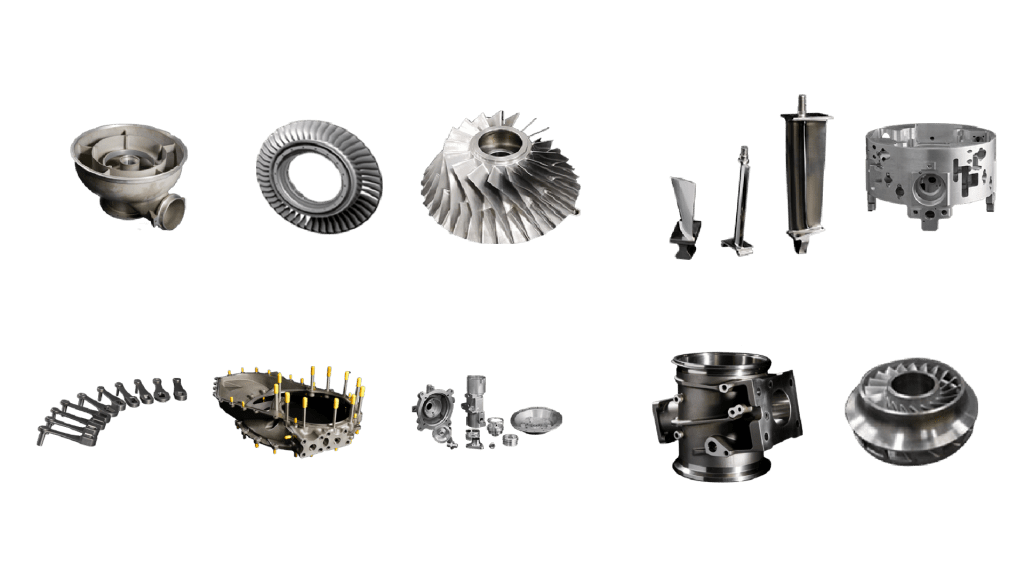

We manufacture medium and highly complex precision components, assemblies/ sub-assemblies that are mission-critical for application of civil and military platforms such as airfoils/ blades for aircraft engines and APUs, body valve, housing mount, housing compressor, fan blisk, mixed flow impeller, housing fan, shell and housing, air frames, aero structures (wing and fin), turbine wheel, nozzle, unison rings, lever arms, hydraulic, fuel inerting, flight control, actuating system and others. These parts are widely made from investment castings, forgings, bar stock, tubes and plates and have a wide spread of usage in various commercial and military platforms. The sub-assemblies comprise of processes including stringent machining, testing, special processes and thermal spray coatings such as high-velocity oxygen fuel coating.

We also manufacture industrial aerospace standard fluid distribution parts, integrated into the aircraft hydraulic systems which spans from nose to tail and left to right ends of the wing of an airplane, for the functioning of all the synchronised hydro pneumatic system. We have developed technology to qualify and test fluid distribution system parts of aerospace. The aerospace fluid distribution parts have approved design to produce from precision forging and bar stock. Forging equipment is of servo control screw type technology and produces control features where parts are used in as finished condition. The materials of construction include steel, aluminium, titanium, super/ exotic alloy and copper alloys of aircraft quality. These parts are manufactured and tested to perform at elevated environments as defined by aerospace standards. For supplying of these parts to end customers, specific parts are required to be qualified by the Performance Review Institute and Qualified Manufacturers List Program.

The products are examined, tested, and evaluated for conformance with standard/ specification requirements and listed on the qualification product list as a qualified product for the specific standard/ specification. The procurement of qualified products reduces the risk of product failure to meet specification requirements. The qualification process to validate and certify the performance of the parts are done with various tests and qualifications. The test equipment for all tests were designed and built indigenously to meet the aerospace standards and qualified to the requirement of certifying bodies like NABL.